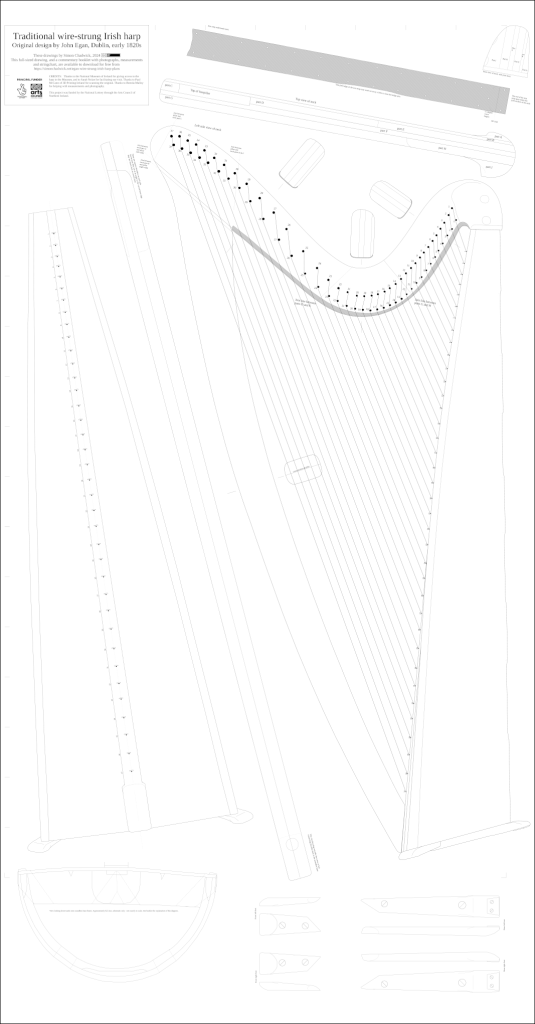

I made these construction drawings in the spring of 2024, to show the design and construction of a traditional wire-strung Irish harp.

The plans are based on a harp made by John Egan in the early 1820s. It has Egan’s serial number 1933, and it was made for the Irish Harp Society in Belfast. It was owned by Robert Bruce Armstrong in the early 1900s, and is shown in the frontispiece to his 1904 book. He gave it to the National Museum of Ireland where it remains today, with the registration number NMI DF:1913.381

I think that this harp was most likely used as a classroom harp at the Belfast Harp School in the 1820s and 1830s, and so many of the traditional harpers working through the 19th century are likely to have taken their lessons using this harp.

The 3D model

The 3D model was made for me by 3D Printing Ireland, based on an on-site scan done by Paul McCann in the National Museum of Ireland. The 3D model gives you a very visceral sense of the overall form and structure of the harp.

Egan Irish harp (National Museum of Ireland) by Simon Chadwick on Sketchfab

You can also download the 3D model from Sketchfab to your own computer.

I dismantled the 3D model into the component parts of the harp, and then made renderings and cross-sections, which I could trace to create my full-sized drawings.

The full-size drawing

The full-sized drawing is 106.7cm wide and 204.2cm long. The actual drawn area is 104.8cm wide.

The full-sized drawing file is a black-and-white PNG at 254dpi (i.e. 10px/mm). There are two different ways to get the full-sized drawing printed out. The first way is to download the full-sized drawing as a single PNG image, which you should be able to send to a large-format printer to have it printed out full size on a big sheet of paper.

Alternatively, I have prepared a 48-page PDF which contains the full-sized drawing sliced up into A4-sized fragments, which you can print full-sized on a normal printer, and cut up and glue together. Make sure the printer does not shrink or scale the PDF as it prints it out.

The full-sized drawing has little gradation marks all down the left side and along the top, every 10cm. There is also a matching pair of marks towards the bottom right of the sheet. You can use these marks to check that your print-out of the plan is correctly scaled to full-size.

If you are unable to print your own copy out, let me know. I have some copies here but they are big and expensive to post. If you are in the UK I can have a copy printed and posted direct to you. If you are in the USA you can contact Rick Kemper who has offered to print copies for anyone who needs them. Otherwise just let me know and I will work out the cheapest and easiest way to get a copy to you.

The commentary booklet

The full-size drawing only shows the exterior of the harp. Because the soundbox is constructed according to standard workshop practices, with a series of internal structures fitted into the curved outer shell, I did not think it would be useful to try and draw these internal structures. Also because of problems with the scanning, we have very little of the internal surfaces captured by the scanner; we only have my rather inaccurate hand measurements.

In the commentary booklet, I have written descriptions of the internal structures, with measurements, and I have also included some photographs of the way the harp is put together. I have also included technical drawings of the tuning pins, and a stringchart. The commentary booklet is an A4 PDF with 22 pages.

Workshop practices

These plans and commentary are really intended for people who already know how to make a harp in the Western tradition. If you need more information about harpmaking, I would recommend Rick Kemper’s online book Building the Lever Harp as a reference to workshop practices. Kemper’s book is very much focussed on the specifics of American-style nylon-strung lever harps, so not everything he says is relevant for this design (because like every harpmaker, Egan had his own idiosyncratic workshop practices, and also he designed this harp from the ground up as a traditional wire-strung Irish harp). But there is plenty enough common ground in workshop practices to make Kemper’s observations and commentary very useful.

Hardware

If you need me to help you out with hardware supplies, you can look at my wire page and my tuning pins page. Or just get in touch and say what you need help with.

Corrections

If you think there is anything important that I have missed out from either the drawing or the booklet, please get in touch and let me know. I can include any changes in revisions of these documents.

There is a lot that we still don’t know about the traditional norms in the design, manufacture and setup of a traditional wire-strung Irish harp. I am eager now to do more study of the other 19th century traditional wire-strung Irish harps by John Egan and by his nephew Francis Hewson. Comparing different examples can give us hints as to what features are important and characteristic, and which features are incidental or accidental design flaws.

Sponsorship

Scanning the museum harps is expensive, and generating the renderings and drawings takes a lot of time and work.

If you would like to sponsor the cost of scanning another harp and generating the renderings and drawings from the 3D model, please get in touch.

If you would like to sponsor the construction of a harp based on these designs, for use in teaching the traditional playing techniques and method of playing to young people, also get in touch.

Credits

Drawings, photographs and renderings by Simon Chadwick, 2024

Free to download, distribute, copy, adapt, use, or re-use without asking permission.

Thanks to the National Museum of Ireland for giving access to the harp in the Museum, and to Sarah Nolan for facilitating the visit. Thanks to Paul McCann of 3D Printing Ireland for scanning the original. Thanks to Brenda Malloy for helping with measurements and photography.

The scans and the drawings were funded by the National Lottery through the Arts Council of Northern Ireland.